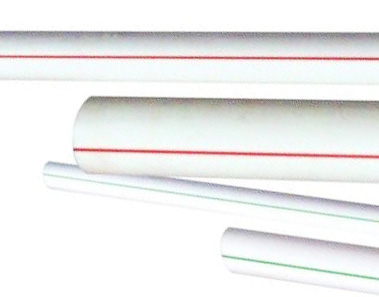

PPR pipes are manufactured from Polypropylene Random Copolymer raw material. This raw material is called Type 3. The most important feature of PPR that distinguishes it from the others is that it could also be used in hot water systems besides being used in sanitary networks. They have been marketed as an alternative to galvanized pipes and in near future they will dominate the market 100 % because of the superiorities they posses. The product has also fittings for connections. They are used for connections and they can be used in any type of transitions. There are fittings with metal parts for connections with the threaded pieces on the line. Socket welding is used as the connection method. Since the product has high welding capacity it is possible to make proper welding after 1-2 hours of training. The production is between Ø20 –Ø315 mm. The product could be produced in different colors.

ENVIRONMENTAL ASPECTS

Fully recyclable product; neither toxic nor otherwise harmful substances are used in its manufacture and/or application.

SYSTEM CHARACTERISTICS AND MANUFACTURING STANDARDS

- Polypropylene plastic piping systems – hot and cold water distribution systems in buildings and heating systems.

- Meeting all health requirements.

- No corrosion and/or encrustation.

- Exceptionally long service life while preserving high utility value.

- Trouble – free operations with less noise.

- Less friction losses than with traditional materials.

- Less weight than with traditional materials.

- Quick, easy and clean installation works.

- Resistance in aggressive environments (e.g. in agricultural applications).

- DIN 8077/8078